Installing a 1.5T small animal MRI machine is no small feat. It’s a complex, multi-week journey involving architects, construction teams, project managers and a whole lot of patience. As Hallmarq’s Regional Customer Success Manager for North America, Vlad Kovalov has been involved in more than a few customer installations. He’s the first to admit it’s a process that demands flexibility, optimism, and… a touch of humour.

Read what Vlad has to say about installing small animal 1.5T MRI as we take a behind the scenes look at what goes on before the scanning can start.

The setup: change is the constant

From the outset, we work with a mix of professionals; architects, builders, and multiple project managers. Sometimes those project managers can change mid-project, which means starting over with new teams who may have new instructions and a revised remit. Dealing with this change requires pivoting when required – and often at the last minute – in order to adapt. It’s something that Hallmarq’s install team are used to and take in their stride. As Vlad puts it…

By the end of it, we are all part-time architects and full-time optimists.”

Vlad Kovolov, Regional Customer Success Manager, NAM, Hallmarq Veterinary Imaging

Despite the chaos, there’s a rhythm to the madness. Teams across the UK and USA collaborate, tweak plans, and adapt to constant change. It’s often stressful, but also strangely enjoyable, bringing out the best as the team works together to ensure the installation is as smooth as possible for the customer.

The essentials: shopping and shimming

Once the MRI is physically installed, the real work begins. That includes sourcing essentials – like distilled water, for cooling the gradient and RF amps. These powerful amplifiers produce so much heat that they must be kept cooled. If they overheat, they’ll stop working.

Surprisingly, Walmart often wins out as the best vendor for the water needed. And, with Hallmarq’s values and ESG in mind, Vlad assures us that every plastic bottle – once emptied – gets recycled properly!

Then comes ‘shimming’ – a critical step to ensure the magnetic field is uniform. “If you’ve ever tried a 5,000-piece puzzle,” Vlad says, “that’s what shimming feels like.” It involves placing tiny plates into hundreds of packets, with long calls to Research & Development and meticulous adjustments. When it’s done right, it’s steak night for the team and a well-earned celebration before the next steps must begin.

Tuning, testing and training

After shimming, we move on to tuning and calibration. This crucial phase involves close collaboration with our R&D and software teams – often working late into the night – and is essential for ensuring the accuracy, consistency, and quality of the acquired MRI images.

Once the system is tuned, we run an acceptance test. It usually takes a day, but getting final sign-off from the customer can take longer as we deal with any queries that may arise. Once that’s done, training with Hallmarq’s in-house team of experts begins, and the clinic can start capturing high-quality images.

The payoff – magic and satisfaction

Every installation is a different story, a few months of our lives, often filled with stress, but offset with teamwork, and satisfaction. Despite his experience and time spent working around MRI machines, Vlad is still in awe of just what the modality enables clinicians to do stating,

MRI still feels like magic! Radio waves go somewhere, and suddenly we can see an animal’s spine and nerves on a screen.”

Vlad Kovolov, Regional Customer Success Manager, NAM, Hallmarq Veterinary Imaging

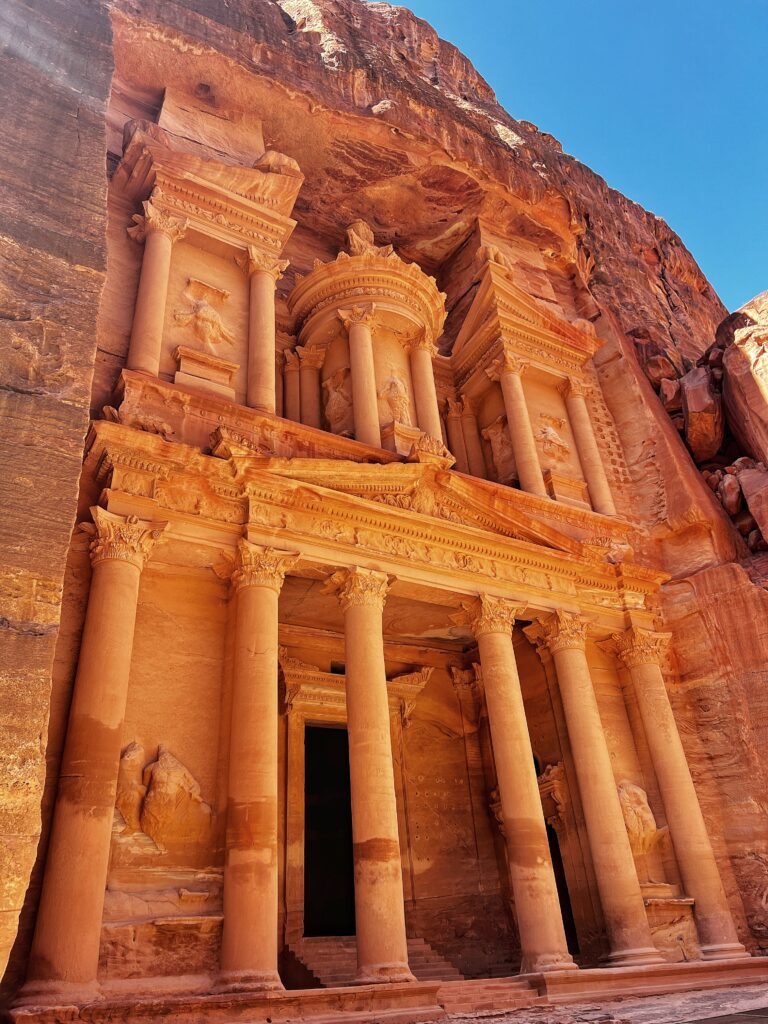

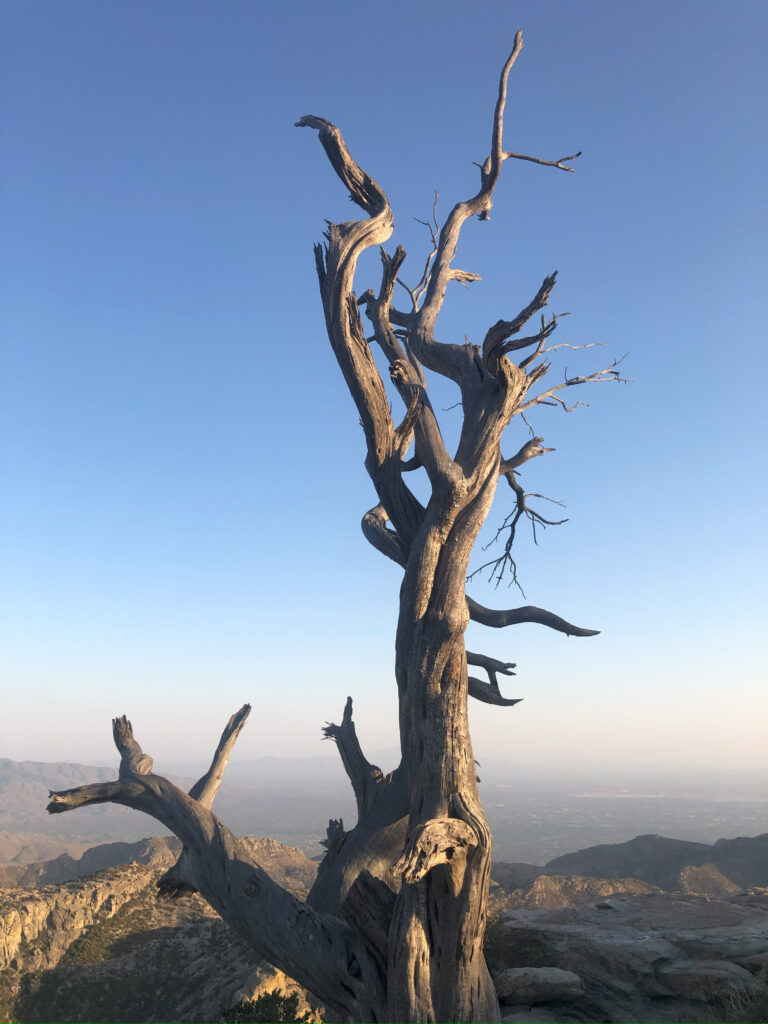

And when the job is done? Vlad finds peace behind the lens, taking time out to photograph the beautiful places near each site to capture a very different kind of image. Those below are just some of the locations that his work has taken him to.

Want to learn more? With the Hallmarq solution, you can remove the cost and complexity of offering small animal 1.5T MRI. Find out how…